Hello all

oh well, machine will work with Mastercam, with the tool height sensor,

reset to the center of the head, posprocesor will know the length of tool - tools magazine in soft.

what the machine - it's easy to build, but time-consuming

Thread: 5AXIS: photos - new build

Results 21 to 40 of 191

-

02-03-2010, 10:55 AM #21

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

-

02-03-2010, 12:20 PM #22

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

The drive mechanisms for this machine is here if anyone is interested.

CarveOneCarveOne

http://www.carveonecncwoodcraft.com

-

02-03-2010, 02:30 PM #23

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

-

02-03-2010, 03:00 PM #24

Registered

Registered

- Join Date

- Jun 2005

- Posts

- 1730

Bartuss sets the standard for BIG on CNCZONE

Bartuss sets the standard for BIG on CNCZONE

Bartuss1,

We must compliment you and your team for putting together such a nice machine. Very good engineering and rather amazing to see something like this assembled in an outside environment. The welding job alone looks awesome. Lots of steel.

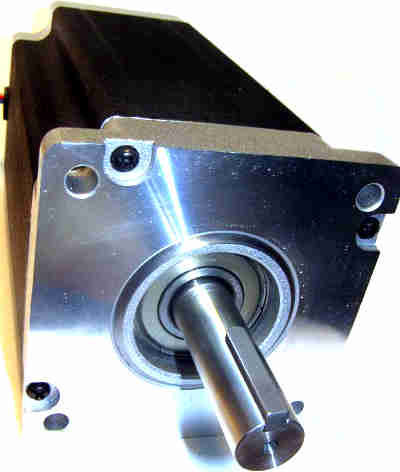

The stepper motors are huge and the machine looks extremely stiff. When you get the motors wired up post a video of the head moving around the machine everyone would like to see your 5 axis machine in motion. Great Job.

Congratulations.

CNCMAN172

-

02-03-2010, 03:45 PM #25

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

When I will end control cabinet on wheels...When you get the motors wired up post a video of the head moving around the machine everyone would like to see your 5 axis machine in motion

so... next, we will make same movies

-

02-03-2010, 04:14 PM #26

Member

Member

- Join Date

- Apr 2007

- Posts

- 8082

My apologies to you sir. The link that I posted was not intended to imply that the small drives were for your very large machine. They are from the same site as the small machine that ghassall posted a photo of. These drives are for someone who has considered building a small 5 axis DIY machine. I see discussions about it on this site and knew where the photo came from.

Your design and component selections are certainly not in the same class of machine. I am very much impressed with your project and workmanship and have lots of interest in seeing more of it.

CarveOneCarveOne

http://www.carveonecncwoodcraft.com

-

02-03-2010, 06:40 PM #27

Registered

Registered

- Join Date

- Apr 2006

- Posts

- 1016

software for 5 axis

What software will drive your 5 axis setup ... mach or.... something else, also Program will you use to generate 5 axis code. Delcam products?

p.s very nice build!

The big obstacle for most users that want to go 5 axis is not so much the build... there are so many vendors that can support that hardware and technical issues.. ie http://www.doughtydrive.com is good example that was brought up.

But it the cost of the application software to generate the g code at a econical diy level with good support to the public on cost effective budget.

The only one that come to mind is….

http://www.cnc-toolkit.com/ not sure which cad package it works best with? maybe some advanced users can comment?

Fyi here a example of http://www.doughtydrive.com/other.html circuit for 5axis

keep the pictures coming, what the gear ratio used on the b/c axis?

-

02-03-2010, 06:57 PM #28

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

model of the project prepared in Mastercam, then post-processor creates G code and sends it to mach3 (or EMC2),

gears of axis B and C is 1:3, stepper motor 50Nm, so torque output is 150Nm, also Z-axis has the same ratio as the unit weighs about 300kg, srew drive Z axis is trapezoidal fi 36mm's with a stroke of 6mm

-

02-03-2010, 09:27 PM #29

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

Today's work

-

02-04-2010, 01:19 AM #30

Registered

Registered

- Join Date

- Feb 2009

- Posts

- 16

-

02-04-2010, 09:25 AM #31

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

Originally Posted by Deep Groove

Originally Posted by Deep Groove

of course -->> Flux Capacitor is planned

Back to the Future - is needed

-

02-04-2010, 06:06 PM #32

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 992

Wow, it's not hobby machine... if that's me with the size that big I will go around hunting job for it.

The best way to learn is trial error.

-

02-04-2010, 07:07 PM #33

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

-

02-04-2010, 07:21 PM #34

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 439

Bartuss-

Are you using front wheel drive automotive bearings? It certainly appears that you are.

Very impressive build and I look forward to seeing videos of it in operation!

Keith

-

02-04-2010, 08:10 PM #35

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

yes, this is rear wheel hub from Mondeo

-

02-04-2010, 08:16 PM #36

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 7

Most setups have a spring loaded pinion to rack. Is that required or just preferred? The fab work so far looks top notch.

-

02-04-2010, 08:24 PM #37

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 202

doesn't need, just a good fit, I tested a similar drive in the plasma cut

-

02-04-2010, 08:27 PM #38

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

notMost setups have a spring loaded pinion to rack. Is that required or just preferred?

because of heavy burden YBC axisrequired

-

02-05-2010, 12:35 AM #39

Registered

Registered

- Join Date

- Aug 2008

- Posts

- 1166

Nice looking build.

What kind of power supplies are planning on using with these servos? I have some servos for my rebuild of my router that are 1kW continuous, ~11kW peak. 1kW is plenty of power for what I'm working on, but I'm also limited to around 1.5kW with the typical transformers and power supplies I can find.

Spring loaded pinions are typically used to reduce backlash. So a heavy axis doesn't help with that issue. Do you just plan to attach the pinion so it is pushed into the rack and taking up most of the backlash and readjust periodically to account for wear?

-

02-05-2010, 12:59 AM #40

Registered

Registered

- Join Date

- Feb 2005

- Posts

- 130

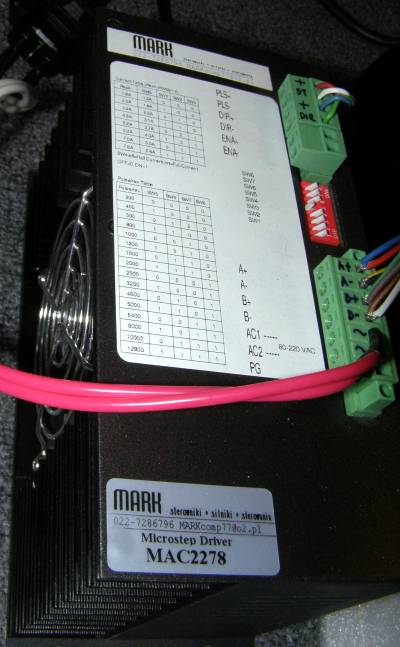

We are going to use BIG stepper motorsWhat kind of power supplies are planning on using with these servos?

for ZBC 50Nm:

http://forum-cnc.pl/index.php?topic=1003.0

for X1X2Y 28Nm:

http://forum-cnc.pl/index.php?topic=759.0

as a stepper motor driver for X1X2YZBC - high voltage driver MAC2278

http://forum-cnc.pl/index.php?topic=1008.0

I have 2kW toroid transformer (soft start etc)I'm also limited to around 1.5kW with the typical transformers and power supplies I can find.

I will use 230/180 to lower max input voltage (max allowed is 230vac)

(in EU mains is 230vac)

this 28Nm motor with powering about 250VDC (180VAC) rotate up to 30..40rot/sec

and 50Nm up to about 20rot/sec

Similar Threads

-

5aXis-USB-iso-BOB

By Yachaan in forum Open Source Controller BoardsReplies: 12Last Post: 09-20-2015, 05:48 PM -

Semi - DIY CNC Router / Mill Project Build (With photos)

By rescueweasel in forum CNC Wood Router Project LogReplies: 17Last Post: 08-30-2014, 06:21 PM -

5axis help

By BOATDUDEGUY in forum Mach Software (ArtSoft software)Replies: 7Last Post: 02-24-2014, 08:08 PM -

My CNC build-up with video and photos + everything a beginner should know

By dmoore in forum DIY CNC Router Table MachinesReplies: 22Last Post: 02-07-2008, 02:53 AM -

5axis Help

By jybute in forum Haas MillsReplies: 0Last Post: 11-22-2006, 03:10 PM

Reply With Quote

Reply With Quote