Hi,

I plan to create vertical gang lathe.

Total length will be 800mm

Linear slide by HIWIN 15mm with AC Servo motor.

Ballscrew dia 15mm pitch 5mm

Headstock 3-jaw chuck will be 3"

Spindle speed 5000rpm

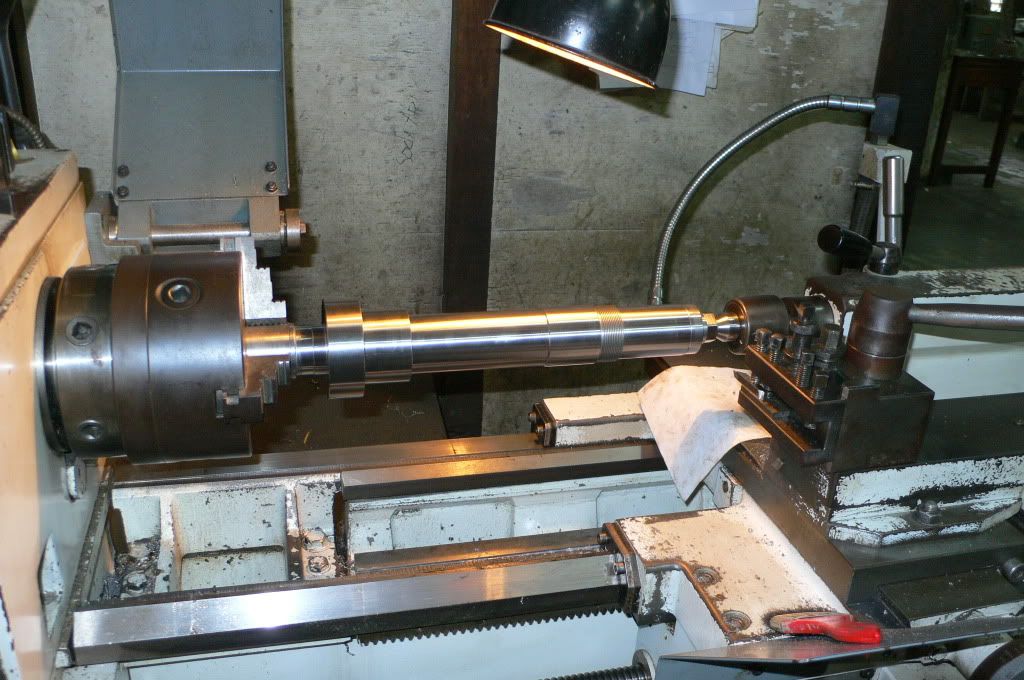

I already start 1 week ago, by turning & grinding the headstock spindle.

Here I do Internal turning.

Finish Spindle, next week do drilling

Thread: CNC Lathe made by Monkey King

Results 1 to 20 of 89

-

02-06-2010, 03:04 PM #1

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

CNC Lathe made by Monkey King

-

02-08-2010, 12:39 AM #2

Registered

Registered

- Join Date

- Feb 2006

- Posts

- 1051

-

03-02-2010, 01:55 AM #3

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Hi,

Finally, I can do the headstock.

Here I do Internal turning.

http://i813.photobucket.com/albums/z...g/P1020487.jpg

-

03-02-2010, 03:15 AM #4

Registered

Registered

- Join Date

- Nov 2005

- Posts

- 264

looks very nice. did you cast the headstock, or bore it to that size?

FS: Complete Z-Axis Assembly with THK RSR15WM slide, leadscrew, stepper mount. PM for more info.

-

03-02-2010, 03:45 PM #5

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

The headstock made by cast iron, boring and finish by grinding.

-

03-06-2010, 02:51 PM #6

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

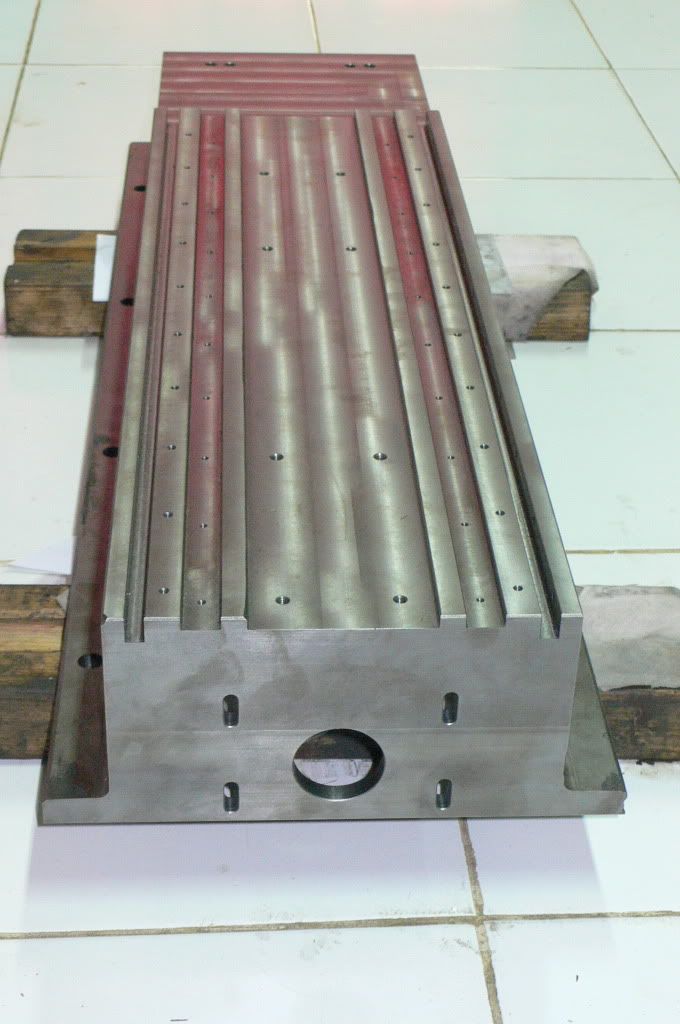

Today I do the bottom of Z body.

See the picture, total length is 800 mm, weight about 120kg.

http://i813.photobucket.com/albums/z...g/P1020575.jpg

-

03-31-2010, 12:39 PM #7

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Here is the riser block, will be put under headstock.

-

03-31-2010, 03:37 PM #8

Registered

Registered

- Join Date

- Mar 2006

- Posts

- 489

That's some fine turning you've done there Monkey King! I can tell you enjoy doing it. I predict that your new lathe will be a work of art.

Take care,

Paul

-

04-07-2010, 01:22 AM #9

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

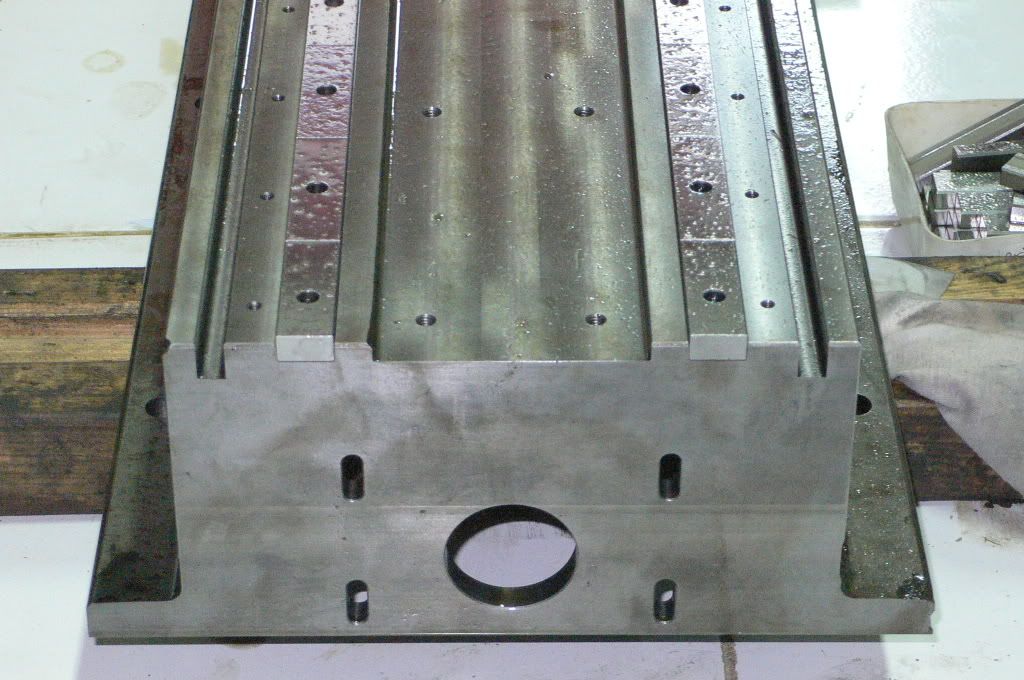

Here is the middle parts between z axis & x axis.

as size reference, 1 ceramic tile = 30 cm.

-

04-08-2010, 07:41 PM #10

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Size estimation of the gang lathe.

-

04-08-2010, 07:54 PM #11

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Wow, that is a serious lump of metal you have there.

Nice design.Regards,

Mark

-

04-26-2010, 12:06 PM #12

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Today I finish the Z Body.

:banana::banana::banana:

-

04-26-2010, 03:40 PM #13

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Nice work. What mill are you using to make this?

Regards,

Mark

-

04-27-2010, 02:19 AM #14

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Hi Mark,

I use cnc kneemill.

-

04-28-2010, 02:08 AM #15

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

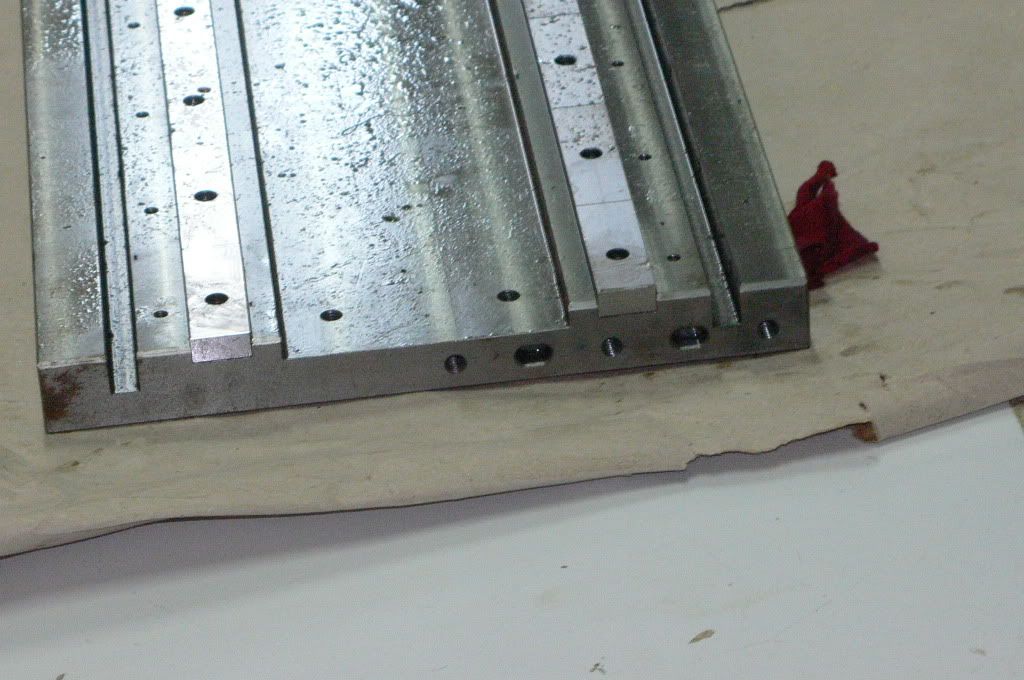

Here another view of Z Body.

-

04-28-2010, 08:21 AM #16

Registered

Registered

- Join Date

- Mar 2004

- Posts

- 1306

Nice toys you have there.

Regards,

Mark

-

04-30-2010, 03:53 PM #17

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Today I drill the bolt hole for lathe spindle. Must be precise to maintain the balance.

Also I grind the middle parts between z axis & x axis.

:banana::banana::banana:

-

05-11-2010, 03:24 PM #18

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

I've done many thing here.

Made the insert to stop the linear rail.

Bearing stopper with grove for oil way.

Holder for servo motor

Ring between bearings.

-

05-11-2010, 04:22 PM #19

Gold Member

Gold Member

- Join Date

- May 2005

- Posts

- 2502

Very nice work!

What bearings will you use on your spindle?

Best,

BWTry G-Wizard Machinist's Calculator for free:

http://www.cnccookbook.com/CCGWizard.html

-

05-12-2010, 02:29 PM #20

Registered

Registered

- Join Date

- Feb 2010

- Posts

- 0

Hi Bob Warfield,

I'll use SKF 30310 J2/Q as back bearing and SKF 32212 J2/Q as front bearing.

:banana::banana::banana:

Similar Threads

-

King 7x12 Lathe

By aarongough in forum Benchtop MachinesReplies: 8Last Post: 01-04-2013, 11:27 PM -

Has anyone ever made their own lathe?

By sanddrag in forum Mini LatheReplies: 11Last Post: 10-30-2011, 04:58 PM -

Polishing Aluminum using Burr King Vibra King 40

By 07vistabluegt in forum MetalWork DiscussionReplies: 4Last Post: 01-24-2011, 11:27 PM -

Purchasing advise on King Canada Lathe vs Elite Lathe

By cmanning in forum Mini LatheReplies: 1Last Post: 05-29-2009, 07:47 AM

Reply With Quote

Reply With Quote