so I was jogging my mill, trying to send the table flying off the x-axis for no particular reason... (well not really, but that is kinda what happened...)

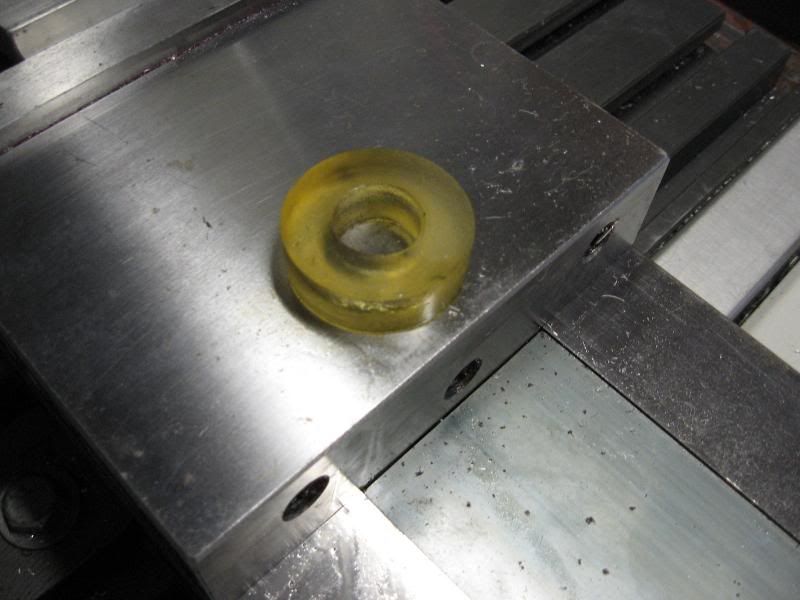

and this part comes flying out:

what is it?

where did it come from?

why does it exist?

where was it trying to go?

was it trying to attack me?

my 100% unqualified, inexperienced random guess would be that it goes on the end of the x axis lead screw, and it is some sort of 'bumper' of sorts to try and stop you from causing the table to fly off...

if so, how does one put it back on? the screw/washer setup that looks like it is there to hold it on is very tight, the stepper can not hold the force required to turn said screw... so getting said screw out seems pretty unlikely...

I guess I could slit it, slide it back where he is suppose(?) to go and then tape him or something? is it worth the effort?

Thread: so whats this part for/do?

Results 1 to 7 of 7

-

06-22-2013, 12:33 AM #1

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

so whats this part for/do?

-

06-22-2013, 01:01 AM #2

Registered

Registered

- Join Date

- Dec 2012

- Posts

- 194

The manual shows the part in the diagrams. Also was the machine powered up when you tried to remove the screw? If not try powering the mill up.

-

06-22-2013, 01:10 AM #3

Gold Member

Gold Member

- Join Date

- Sep 2012

- Posts

- 1543

It is the X bumper, but look at it this way, you have more travel now.

-

06-22-2013, 01:11 AM #4

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 714

I was just looking at those on my machine and you assumed correctly sir! I was wondering if that would stop the travel if it missed the limit switch. Maybe a radiator hose clamp around it after slitting it to get it back on. Maybe a strap wrench on the end of the shaft to hold it while trying to loosen the screw/nut?

Good luck with it........mike sr

-

06-22-2013, 01:13 AM #5

Gold Member

Gold Member

- Join Date

- Sep 2012

- Posts

- 1543

I moved my limit switches when I first got the mill, I bumped into the bumpers a few times, they never popped off tho. I just set my limits to just missing the bumper, since it references at a slow speed I was never worried, I keep track of my 10x18" machine coordinates regularly so I know I won't hit them At 150ipm...

-

06-22-2013, 02:17 AM #6

Registered

Registered

- Join Date

- Jul 2011

- Posts

- 297

yea machine was powered up when I tried to loosen that bolt...

I think I may try just slitting it and using mike's hose clamp idea... seems like a bumper is a nice thing to have, but not something you necessarily want to need/use...

-

06-22-2013, 03:30 AM #7

Registered

Registered

- Join Date

- Jan 2012

- Posts

- 714

mike sr

Similar Threads

-

Whats in my box

By belkrem in forum Chinese MachinesReplies: 8Last Post: 10-04-2013, 02:23 PM -

servo setup whats need and whats do i need to know

By jhtmfg in forum Benchtop MachinesReplies: 0Last Post: 10-10-2009, 12:29 AM -

Whats the most expensive part you've worked on?

By Chuck Pressure in forum MetalWork DiscussionReplies: 68Last Post: 11-06-2007, 08:13 PM -

Whats it for?

By bearwen in forum DIY CNC Router Table MachinesReplies: 1Last Post: 03-09-2006, 09:46 PM -

Whats wrong with this freaking rectifier part II

By Noah in forum CNC Machine Related ElectronicsReplies: 19Last Post: 07-09-2004, 02:41 AM

Reply With Quote

Reply With Quote