Thread: Started new project

Results 41 to 56 of 56

-

06-20-2007, 03:24 AM #41

-

06-22-2007, 02:51 PM #42

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 44

know someone who makes vehicles for defence and transpor purposes.still gotta look into his shop.what should i be asking for since he says hell help out??

__________________i dont know sqat!!! will be asking dumb questions

-

06-22-2007, 06:11 PM #43

-

06-23-2007, 04:18 AM #44

Got the slots for motor mounting milled last night(forgot to snap some pictures, will do on monday). But this morning i got a crazy idea of just tapping motor mounting holes instead of using bolt and nut. Does anyone see problem with doing that? The holes are drilled correct size for M6 tap, which is nice.

So my question is: Is there any reason for not doing it this way?

-

06-23-2007, 04:26 AM #45

Registered

Registered

- Join Date

- May 2006

- Posts

- 1469

Will you still be able to adjust belt tension?

-

06-23-2007, 04:27 AM #46

Yes, it would work exactly same way, just no nut on top...

-

06-23-2007, 10:14 AM #47

Registered

Registered

- Join Date

- Jun 2007

- Posts

- 44

i dont know sqat!!! will be asking dumb questions

-

07-15-2007, 01:25 AM #48

Have been pretty busy with work around the house for last few weeks. Got little more work done on router mount. All thats finished to do on it is weld some brackets and weld pipe to C channel.

Also this is what i'm going to do for table: 1.5"x1.25x.25 square tubing. either welded or bolted togheter, reason for doing this this way is that i got few sections of that square tubing for free:wee:

Hopeing to get some welding done tonight...

-

09-27-2007, 05:05 PM #49

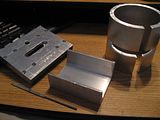

time to update this thread once again. I did get the table welded that time. Here are few pictures:

that is some Corian on top. The table still needs to be surfaced, hopeing to do it some time soon.

-

09-27-2007, 05:07 PM #50

also was wondering which way is better to post pics? clickable thumbnails or full size?

-

09-27-2007, 05:15 PM #51

-

09-27-2007, 05:18 PM #52

-

09-27-2007, 05:21 PM #53

forgot to mention that everything will be in rack mount drawer, 3U

-

09-27-2007, 07:25 PM #54

Registered

Registered

- Join Date

- Nov 2006

- Posts

- 1698

rustamd, that all looks really really great. It looks like your showing off your nice aluminium welding, was that done with Mig? Its NICE.

Wow thats an open question.....maybe lots of nuts and bolts, steel plate, belts, gears. Could you get a strong vacuum pump that you could rig up somhow? Perhaps some sort of cannon just to sit on top and look cool... ... Let your imagination run wild!

... Let your imagination run wild!

-

09-28-2007, 12:20 AM #55

Thank you. All welding was done by my friend, TIG, he asked to show it off

-

05-31-2009, 04:12 AM #56

Time to bring this old thread back up. After long break from buiding machine, $ problems and health problems I'm starting to work on it once again, last couple days I worked on cable guides, machine is almost ready, just need to run wiring/hook up limit switches/ double check controller, its been like 2 years since i looked into cnc stuff, got to make sure its all ok and hoping to make some chips soon, will get some updates pics soon aswell

Similar Threads

-

getting started

By richaevans in forum CNC Wood Router Project LogReplies: 2Last Post: 08-21-2006, 04:34 PM -

getting started

By richaevans in forum CNC Wood Router Project LogReplies: 1Last Post: 08-18-2006, 08:20 PM -

Finally Started My Router Project

By Ozinus in forum CNC Wood Router Project LogReplies: 19Last Post: 07-18-2005, 11:46 PM -

Getting Started

By PaulSwany in forum DIY CNC Router Table MachinesReplies: 8Last Post: 04-13-2004, 10:25 PM -

If you were to just get started.

By rustranch in forum DIY CNC Router Table MachinesReplies: 6Last Post: 09-24-2003, 03:11 PM

Reply With Quote

Reply With Quote sorry

sorry