Good thread. Ok, why do you need a voltage divider?

Thread: Rod's Aussie Plasma Build

Results 21 to 33 of 33

-

07-30-2015, 11:47 AM #21

Re: Rod's Aussie Plasma Build

-

07-30-2015, 12:11 PM #22

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Rod's Aussie Plasma Build

Mikie, the better plasma cutters have one built in but the cheapies (like mine) don't. The purpose of the voltage divider is to reduce the voltage on the Plasma electrodes to a measurable level. Typically the divider is 20:1 or 50:1. eg. at 50:1, 100 volts on the arc is reduced to 2 volts. Not sure what this card divides by.

Anyway, I have not got much done. The socket for the voltage sensor on the plasma has turned up, I've also got a replacement power supply on hand. Decided to go with a 24 Volt power supply as the THC controller has a 5 volt output for breakout boards.

I got withdrawal symptoms. Last night decided to machine up a machine torch out of a length of Acetal (Delrin). A nice plastic to machine, much nicer than the HDPE I usually machine.

I hope I can get the plumbing fittings for the other end of the plasma cable so I can use this on my plasma cutter

I can't move in my tiny shed so I have to get the plasma cutter and controller box back together and reclaim some space. Then I'll work on the Z axis which will take a while at the pace I've been making.

As an aside, I got a bit excited with what Scott has achieved using the rotary table controller I developed for an Arduino. He's using it to index on a CNC machine that does not have 4th Axis support.

Heavy Duty Arduino Dividing Head Project

so I put a thread about it here on the zone

http://www.cnczone.com/forums/arduin...ml#post1739252Rod Webster

www.vehiclemods.net.au

-

07-31-2015, 10:24 PM #23

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 60

Re: Rod's Aussie Plasma Build

Nice work on the torch body Rod, head down bum up.

You do realise we are having a race to the finish lien don't you ;-)

I am having problems getting motivated lately.

-

08-02-2015, 09:35 AM #24

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Rod's Aussie Plasma Build

Thanks Willy, Dunno about the race, but not being able to get into my shed for plasma debris has been a motivator for me...

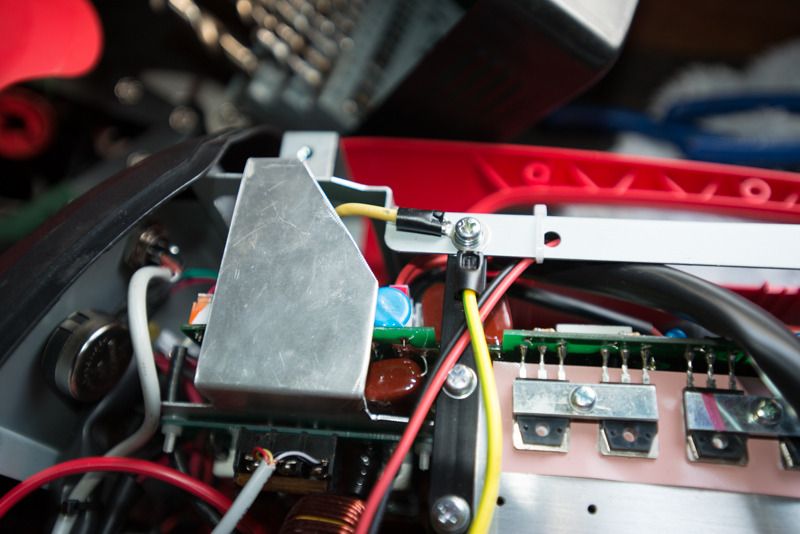

Anyway, this weekend, started with closing up my plasma cutter. Had to snip off a bit of the brackets that fouled the case

And then it went together nicely. 2 pins for the voltage divider and a third for the earth shield.

And following feedback on this thread, I decided to make a cap to keep the contacts clean if in manual mode.

Only took a few minutes on the lathe and let the thread on the connector to cut a thread in the Acetal (Delrin) cap.

Then spent the rest of the weekend wiring up the stepper controllers and 24 volt relays for the THC

For the Aussies, I bought the relays from Jaycar and chose this style because they looked the same as the ones in the THC manual

The black Relay base is designed to mount to a DIN rail but also bolt on and the relays just clip in.

I also mounted up a Meanwell 24 volt power supply which is a drop in replacement for the 12v/5v dual rail supply so no modifications to the case was necessary . Happy about that.

So I think this layer of hardware is complete. The 48V and 24 V power supplies mount above this and the THC and break out board will be on a layer below this one.

My friend Chris kindly provided me with some high quality shielded 4 core cable. He tells me I owe him a carton off beer now. I'm using 5 pin connectors so that the shield can pass through the case. Still waiting on an order to turn up. the colour coded wires came from a left over length of 7 core trailer wiring cable. Need a bit more for one more axis. I used this becasue it was heavier than the hookup wire I have here.

The relays are to turn the Plasma torch on and to trigger an ARC-OK signal at the Breakout Board. I am assuming I just need to run 5 volts through the relay for this one.

I still have to make some mounting plates for all the sockets and decide how it will all go together.Rod Webster

www.vehiclemods.net.au

-

08-04-2015, 12:25 PM #25

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Rod's Aussie Plasma Build

I've wasted plenty of time checking out the awesome builds on this forum and the Z axis is coming together in my head. I realised that I had just about everything here to add a plate marker/engraver (24 volt air solenoid, an air ram and a couple of air regulators) so I ordered one of these tonight so I can incorporate it into the build. The Air ram has about 6" travel

https://www.vektools.com.au/m7-air-engraving-pen.html

I know you US guys are using Chicago engravers but they are pretty hard (and expensive) to find. This one seems readilly available but I passed up the $170 one on eBay that is absolutely identical in favour of this one at $126 delivered.

I'm quite taken by the simplicity of the Proma Z axis design shown here

Plasma - detection of material

So I think I will have some variant of this when I am done.

Proma also have a Linux CNC config for a standalone torch controller I will look into when I get some electronics wired up.

Plasma THC - LinuxCNC

This is also available on the LinuxCNC forum (not sure if it is related or not) so I'm certain I'll get the software side sorted out one way or the other

LinuxCNC :: Topic: THC config that works. (1/6)

I seem to have so little time to play with this and for the last couple of nights have been dragged into my shed to do some machining in the evenings that is paying for this project. IT was hard to get motivated but I better not complain...Rod Webster

www.vehiclemods.net.au

-

08-08-2015, 02:43 AM #26

Registered

Registered

- Join Date

- Feb 2007

- Posts

- 60

-

08-09-2015, 05:34 AM #27

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Rod's Aussie Plasma Build

I figure if I don't do a bit each weekend, I'll never reclaim my shed so I manged to mount up the THC controller box and the Breakout board

It's not shown, but the DB25 cable passes though a rubber grommet to the outside world though matching slots in the face plate and case.

I thought about making a start on the wiring but did not have enough time to get it done today so decided to tackle it another day. I did spend a bit of time getting my head around which pin on the BOB does what in Linux CNC though Rod Webster

Rod Webster

www.vehiclemods.net.au

-

08-30-2015, 10:54 AM #28

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

Re: Rod's Aussie Plasma Build

I know this thread has stalled for a while. That is because I've been busy and also quite unwell with a flu that has made my asthma flare up the worst its been for about 4 years. I got some quality time Over the weekend and finally got all the controller wiring done. Unfortunately, weeks of rolling around on my bench loosened the round microphone connector on the LCD display and constant rotation broke off three wires on the back of the plug. Rather than guess, I've decided to wait until I sort out a pinout before repairing it. Here's the pic completed from the first post that shows the connector in question.

Anyway, no smoke has escaped so far

I've also finally added a parallel port connector to my MiniITX motherboard on my PC and temporarily wired up some stepper I can plug in to the connectors I have added. I'll post up some pics when I get a chance.

I'm not really sure where this build is going to go. We went and looked at a 130 amp 1500mm x 3000mm Hypertherm High Definition plasma cutter table at work the other day (I started this project before I started working there)

Very impressive machine, can also drill and tap with an added auto tool changer but we don't need that capability. By default it is set up to handle up to 5 gases and can do plate marking using acetelyne.

We are spending enough on outsourced laser cutting to just about make it viable to make the investment as the plasma will be accurate enough for everything we cut except one part with a value of about $2.50 a piece. Not sure I'd use mine if I have access to it...Rod Webster

www.vehiclemods.net.au

-

08-30-2015, 03:41 PM #29

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 1189

Re: Rod's Aussie Plasma Build

If you want to sell yours PM me

- it would save me a lot of time ...

- it would save me a lot of time ...

Gesendet von meinem SM-N9005 mit Tapatalk

-

08-30-2015, 10:35 PM #30

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

-

08-31-2015, 06:38 PM #31

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 1189

Re: Rod's Aussie Plasma Build

Austria hart of Europe. ..

Gesendet von meinem SM-N9005 mit Tapatalk

-

09-01-2015, 08:38 AM #32

Registered

Registered

- Join Date

- May 2015

- Posts

- 686

-

09-01-2015, 03:25 PM #33

Registered

Registered

- Join Date

- Oct 2010

- Posts

- 1189

Re: Rod's Aussie Plasma Build

It will be around the globe i guess ... you Are right that is not economic ...

Gesendet von meinem SM-N9005 mit Tapatalk

Similar Threads

-

AUSSIE Plasma Build

By WillyInAus in forum CNC Plasma / Oxy Fuel Cutting MachinesReplies: 24Last Post: 08-08-2015, 03:00 AM -

Another Aussie Build

By Rodm1954 in forum CNC Wood Router Project LogReplies: 47Last Post: 10-26-2010, 03:03 PM -

Aussie Sieg SX3 build

By Chilli in forum Benchtop MachinesReplies: 28Last Post: 07-26-2010, 05:14 AM -

Router Build Help (Aussie)

By twistedfuse in forum CNC Wood Router Project LogReplies: 221Last Post: 07-07-2008, 01:32 PM -

Another Aussie Router build

By Matty Zee in forum CNC Wood Router Project LogReplies: 19Last Post: 05-05-2008, 10:19 PM

Reply With Quote

Reply With Quote